3D Printed Dining Chair

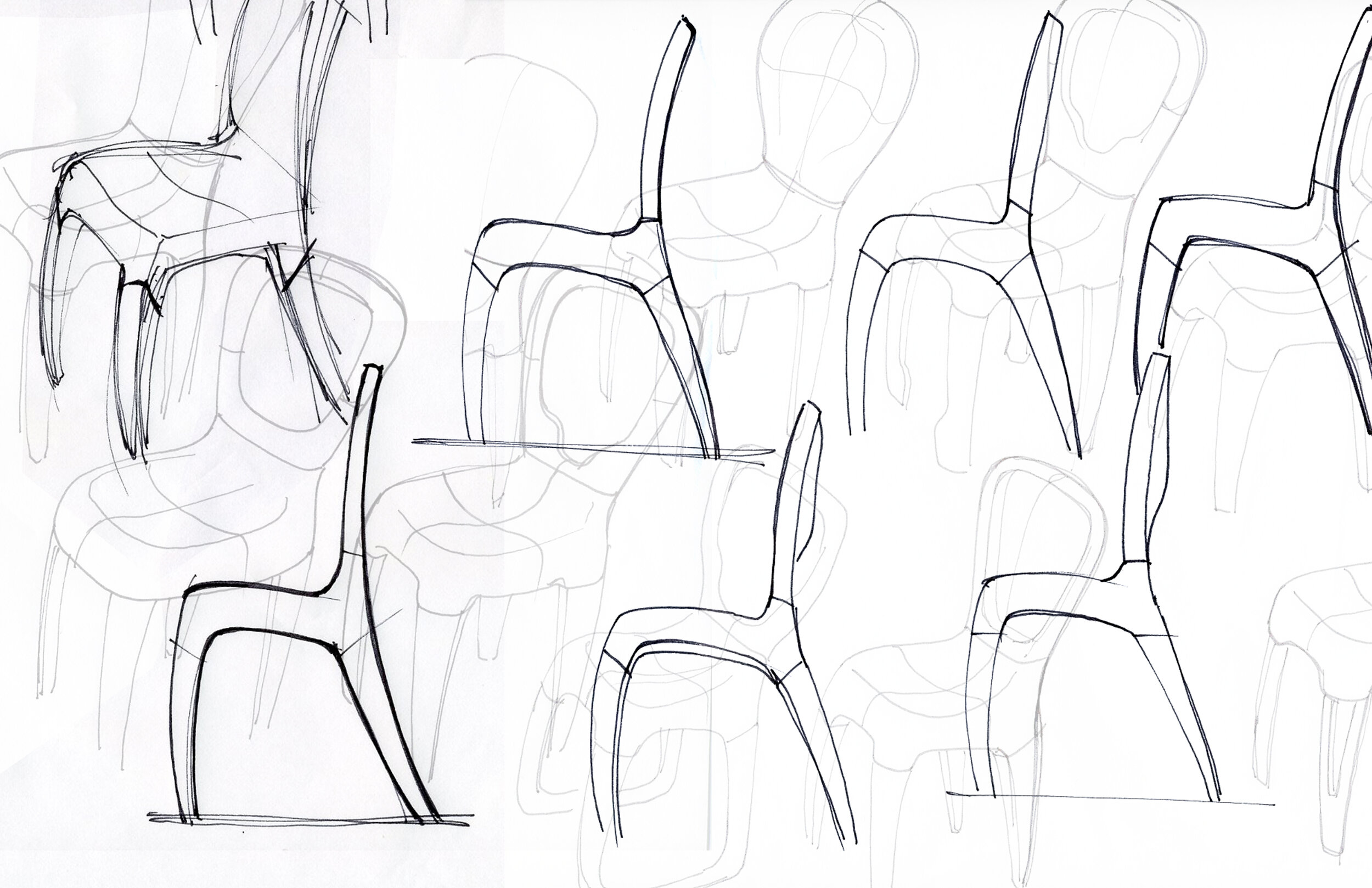

Sketching

Sketching is the way industrial designers think through ideas and communicate. Sketching is also how we start almost every form related project and this was no exception. We typically do hundreds of sketches to get to a single concept.

3D Modeling

Computer Aided Industrial Design (CAID) is used through-out every project and we can deliver solutions in most any CAD package you prefer. We like Autodesk Alias Design Studio because of its NURBS based modeling which helps us create super complex forms. We built countless variations of the design to get the form just right.

CNC Prototyping

We used CNC machining to build solid Urethane Foam and ABS versions of the design to test ergonomics and structural integrity. Improvements were made to the design at each step. Building full scale is always the best way to evaluate a design.

Print 1

The design needed to be modified slightly to fit the build envelop. We experimented with several materials and infill patterns to find the most effective.

Print 2

The design was printed without any support material to reduce build time and create a better final surface quality. The Chair took a total of 91 hours to print.

Assembly

The two pieces were bonded together with epoxy. The chair is made from translucent Ruby red PLA.

Wendell Approved

This project was inspired and mentored by our friend Wendell Castle. Here is the final design at Wendell Castle Studios in Scottsville, NY.

Final Design

The final design photographed by Hal Silverman.

Texture

It was important to get the final surface finish to look refined and unique without any post processing.